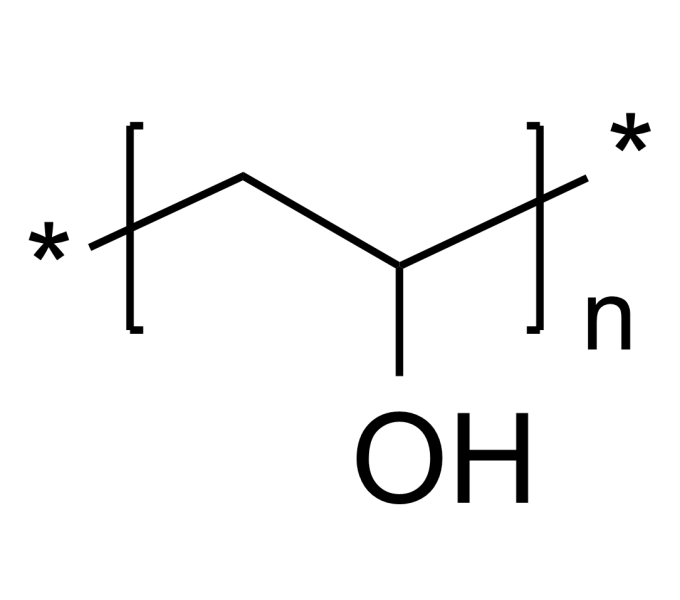

In today’s rapidly evolving world of polymer science, polyvinyl alcohol (PVA) continues to capture the attention of researchers and innovators alike. Known for its unique combination of water solubility, film-forming ability, and biocompatibility, PVA is playing a key role in shaping sustainable materials and advanced technologies.

Unlike many common polymers, PVA is not made by direct polymerization – its monomer, vinyl alcohol, is too unstable. Instead, PVA is produced through the hydrolysis of polyvinyl acetate (PVAc), resulting in a versatile material with wide-ranging uses, from eco-friendly packaging to biomedical devices.

Polyvinyl Alcohol (PVA) is a highly versatile, water-soluble synthetic polymer known for its exceptional adhesive strength, film-forming capabilities, and effective emulsifying properties — making it ideal for industrial, pharmaceutical, and packaging applications. It is widely used across industries, including pharmaceuticals, packaging, industrial applications, and advanced scientific research.

PVA is also nontoxic, resistant to oils and solvents, and biodegradable under certain environmental conditions, such as in composting or when specific microbes are present. These characteristics make it a standout material for applications requiring both performance and environmental responsibility.

As industries shift toward greener and more efficient materials, PVA offers a rare combination of biodegradability, chemical functionality, and mechanical performance. Its versatility allows researchers to design innovative solutions in areas like smart hydrogels, sustainable packaging, and medical devices.

This adaptability – coupled with its safety and performance – continues to make PVA a preferred choice for labs, startups, and R&D teams pushing the boundaries of material science. Importance of Material Quality When it comes to performance, material quality matters. From molecular weight to degree of hydrolysis, the correct specifications can make all the difference in your research outcomes. Polymer Source offers high-purity, research-grade polyvinyl alcohol (PVA) with customizable options to meet diverse scientific and industrial needs. Whether you’re working on nanocomposites, medical-grade materials, or biodegradable films, our expert team ensures you get the correct formulation backed by technical support and global distribution.

Polyvinyl alcohol is more than just a functional polymer – it’s a platform for innovation in everything from green chemistry to biomedical engineering. As the demand for sustainable and high-performance materials grows, PVA remains a key enabler of progress.

To get the most out of this remarkable polymer, it’s essential to work with a trusted supplier. Polymer Source is proud to support researchers and developers around the world with reliable, high-quality PVA and other specialty polymers – tailored to meet the demands of today’s most advanced projects.

Contact us today to discover how our high-quality polymers can enhance your R&D efforts. Our team is committed to supporting you throughout every stage of your project.